6 axis industrial robot. 1550 mm arm reach and 20 kg payload. Equipped with the powerful IRC5 controller.

The IRB 2400 in its different versions and best accuracy, gives excellent performance in material handling, machine tending and process applications. IRB 2400 offers you increased production rates, reduced lead times and faster delivery for your manufactured product.

- Reliable – High production up time

IRB 2400 is the world’s most popular industrial robot The robust construction and use of minimum parts contribute to high reliability and long intervals between maintenance. - Fast – Short cycle times

Thanks to the ABB´s unique motion control of the robot optimizes the acceleration and retardation, which results in shortest cycle time possible. - Accurate – Consistent parts quality

Best in class regarding path accuracy and position repeatability (RP = 0.06 mm) - Strong – Maximized utilization

Payload options are between 7 -20 kg. Max reach 1.810 m. - Robust – Harsh production environment

IP 67 classified, steam washable, clean room (class 100) and “Foundry Plus” optional. - Versatile – Flexible integration and production

All models offered with inverted mounting capability.

Robot Info

Maximum Load of Robot: 20 Kg.

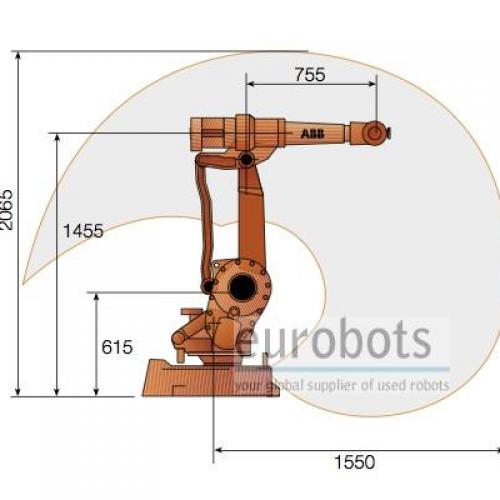

Maximum Reach: 1550 mm.

Repeatability: 0,15 mm.

Controller: IRC5 M2004

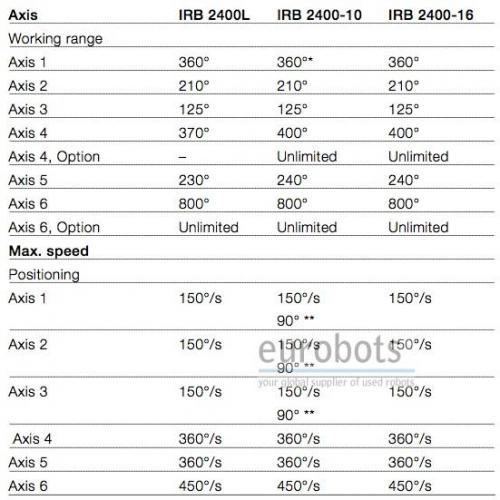

Robot Motion Speed

Axis 1: 150º/s

Axis 2: 150º/s

Axis 3: 150º/s

Axis 4: 360º/s

Axis 5: 360º/s

Axis 6: 450º/s

Robot applications

Arc welding

Material handling

Polishing

Machining

アプリケーション

アーク溶接 , 部品のロードとアンロード , 機械加工 , 部品の取り扱い , 研磨 , 測定 , 部品の組み立て , プラズマ切断

写真

ビデオ

設計図