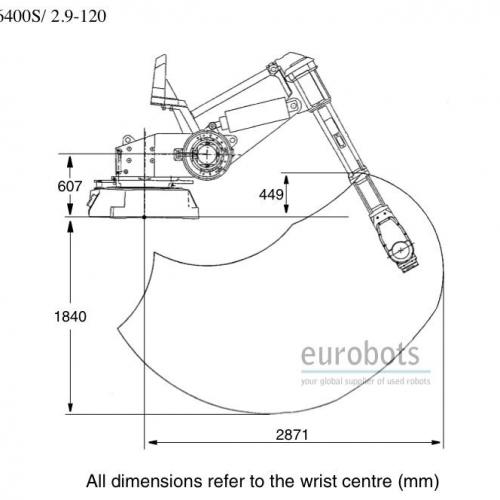

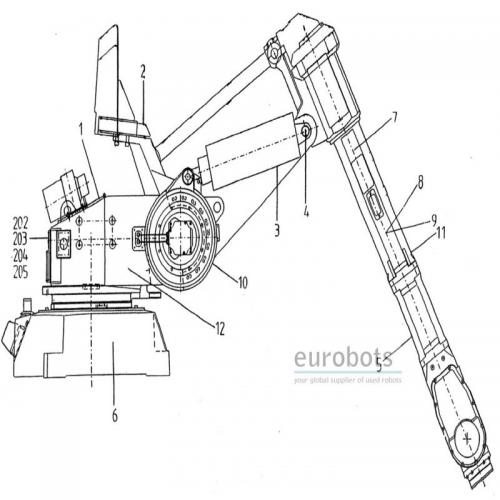

ABB IRB6400S Shelf

Year 2001. Shelf edition of the famous 6400 equipped with the modern S4CPlus controller. Suitable for press transfer and unloading of machines from an elevated position.

The 6-axis IRB 6400 manipulator and S4Cplus robot controller provide short and precise cycle times, rapid change-overs and consistently high process precision.

The family of 6400 robots consists of different arm variants and payload categories which are controlled by the advanced dynamic model based control function, QuickMove, always ensuring the highest acceleration, path accuracy and speed over the entire working envelope.

S4Cplus gives you superior motion control. It features dynamic model based control, QuickMove for short cycle times, and the TrueMove function for high precision path following ability independent of robot speed. The S4Cplus system configuration capability and the powerful programming language RAPID make it easy to set up the controller for a wide range of applications. Two built-in Ethernet channels provide for easier service and factory networking. There are field bus and serial channels for PLC and PC connections. The controller supports TCP/IP, DNS and other protocols. A dedicated robot protocol, RAP, is available for control and monitoring.

Robot Info:

- Number of axis: 6

- Maximum Load of Robot: 120Kg.

- Maximum Reach: 2900 mm.

- Repeatability: 0,15 mm.

- Controller: M2000 S4CPlus.

Robot Motion Speed:

- Axis 1: 100º/seg

- Axis 2: 100º/seg

- Axis 3: 100º/seg

- Axis 4: 210º/seg

- Axis 5: 150º/seg

- Axis 6: 210º/seg

Robot Applications:

- Spotwelding

- Press tending

- Material handling

- Machine tending

- Palletizing

- Assembly

アプリケーション

写真

設計図

English

English

Spain

Spain

Germany

Germany

France

France

Russia

Russia

China

China

Argentina

Argentina

Portugal

Portugal

Colombia

Colombia

Italy

Italy

India

India

Brazil

Brazil

Mexico

Mexico

Turkey

Turkey

Ukraine

Ukraine

Peru

Peru

Sth. Africa

Sth. Africa